Apr 28, 2017 Gildemeister Sprint 32 Swiss-Type Lathe. DMG-MORI HSC 105 linear A Milling Machine High Speed. Gildemeister Sprint 32-8 - Duration: 1:59. 1 1/4' DMG Mori Seiki Sprint 32/8 #404217. Manufacturer: DMG Mori Model: SPRINT 32-8 1 1/4', DMG Mori Seiki Sprint 32/8, Fanuc 32iB, Live Tooling, Barfeed, Mist Coll To the best of our knowledge all details listed below are deemed correct. It is the buyer's responsibility to confirm all details.

- At the upcoming IMTS in Chicago from September 12-17, 2016, DMG MORI will show the SPRINT 32 8 as a US premiere. With the new SPRINT models, GILDEMEISTER Italiana has expanded its portfolio of automatic lathes to include an additional size for bar material with diameters up to 1.3 in. Thus giving DMG MORI customers an even greater choice of manufacturing solutions for minimum cycle times.

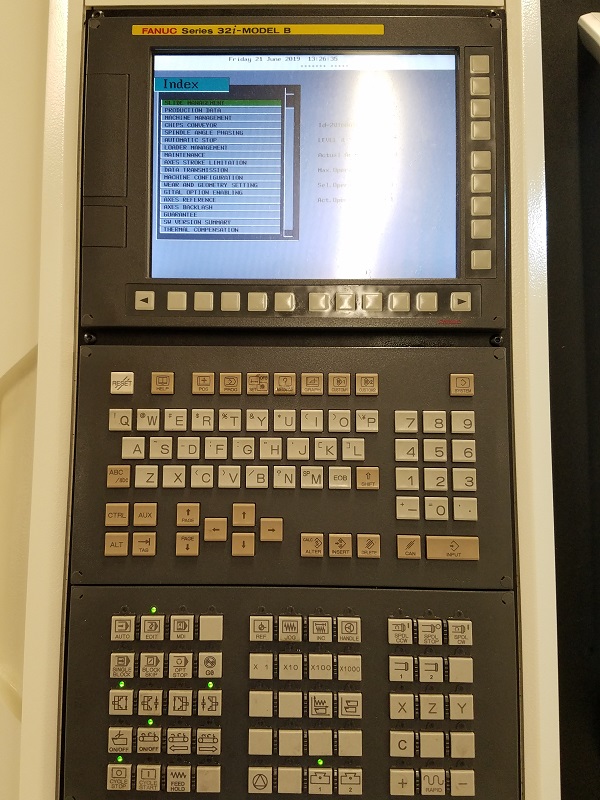

- 1 1/4' DMG Mori Seiki Sprint 32/8 #404217. Manufacturer: DMG Mori; Model: SPRINT 32-8; 1 1/4', DMG Mori Seiki Sprint 32/8, Fanuc 32iB, Live Tooling, Barfeed, Mist Coll To the best of our knowledge all details listed below are deemed correct. It is the buyer's responsibility to confirm all details.

- Gildemeister DMG Sprint 32 Linear 8 Axis Sliding Head Lathe 8 Axis Sliding Head Lathe with Ge Fanuc 160i-B Control System, Maximum Spindle Speeds Main 8000rpm Sub 5000rpm Driven Tool Speed 5000rpm, Axis Travels X1= 50mm Y1=350mm Z1=120mm X2=265mm Y2=235mm Z2=320 C1=360 degrees C2=360 degrees, Maximum Turning Diameter 32mm, Parts Conveyor, Swarf Conveyor, Iemca.

- Gildemeister DMG Sprint 32 Linear 8 Axis Sliding Head Lathe 8 Axis Sliding Head Lathe with Ge Fanuc 160i-B Control System, Maximum Spindle Speeds Main 8000rpm Sub 5000rpm Driven Tool Speed 5000rpm, Axis Travels X1= 50mm Y1=350mm Z1=120mm X2=265mm Y2=235mm Z2=320 C1=360 degrees C2=360 degrees, Maximum Turning Diameter 32mm, Parts Conveyor, Swarf.

Automatic turning with 5 linear axes and up to 2 C-axes

- Main spindle with 8,500 rpm, 40,4 Nm, 5,5 kW

- Counter spindle with 8,500 rpm, 14 Nm, 2.2 kW

- SWISSTYPEkit optional for short and long part turning on one machine

Total of 28 tool stations

Sprint 32 8 Dmg Mori Online

- Up to 10 driven tool stations, 8 driven tool stations as standard, 2 frontal driven stations besides counter spindle optional

- Driven tools spindles 6,000 rpm, 3 Nm, 1 kW

Control panel with 10.4' colour display and FANUC 32i

- 2 control channels, 6 linear axes and up to 2 C-axes

- Tool Monitoring System with graphical tool load display as option

- Up to 3 tools working simultaneously

Sprint 32 8 Dmg Mori Price

DMG MORI has now expanded its series of automatic lathes equipped with a SWISSTYPEkit to include the SPRINT 32|5 and SPRINT 32|8 for bar material with diameters of up to 1.3 in.. Their capability of machining both short and long components with an equal degree of excellence makes the SPRINT models with SWISSTYPEkit the machines of choice in the DMG MORI range. The machine tool manufacturer presented the SPRINT 32|5 and the SPRINT 32|8 as an expansion option with two additional axes at last EMO in Milan. At the upcoming IMTS in Chicago from September 12-17, 2016, DMG MORI will show the SPRINT 32|8 as a US premiere. With the new SPRINT models, GILDEMEISTER Italiana has expanded its portfolio of automatic lathes to include an additional size for bar material with diameters up to 1.3 in. thus giving DMG MORI customers an even greater choice of manufacturing solutions for minimum cycle times.

Sprint 32 8 Dmg Mori Review

Following in the footsteps of the smaller SPRINT 20|5, the SPRINT 32|5 and SPRINT 32|8, as versatile, top-performance automatic lathes, fit perfectly into the GILDEMEISTER Italiana product family. With a footprint of just 30.1ft², the two new models are the most compact machines in their class while at the same time offering a large work area for workpieces of up to ø 1.3 in x 23.6 in.

The two new SPRINT models derive their versatility from the proven SWISSTYPEkit, which enables both short and long turning on one machine – with setup times of less than 30 minutes. To achieve this, the spindle stroke is lengthened from 4 to 10 in. An optional quick tool-change system reduces setup times by another 20 percent.

Comments are closed.